Jrg Weimann / EyeEm//Getty Images

Thermal power plants (TPPs) supply most of the energy demand in developing countries. They have a great environmental importance due to huge amounts of waste produced. In Turkey, the total installed power is 75082 MW. Its 43000 MW comes from thermal power plants (by 2018).

TPPs can have different system modifications, but eventually, they all depend on the logic of burning fuels (e.g. anthracite, lignite, petroleum products, natural gas) and obtaining a thermal energy to rotate the turbines. However, types & amounts of process wastes highly depend on the system modification. TPPs can be categorized in two: 1) Thermal Power Plants with Conventional Steam Turbines, 2) Combined Cycle Power Plants.

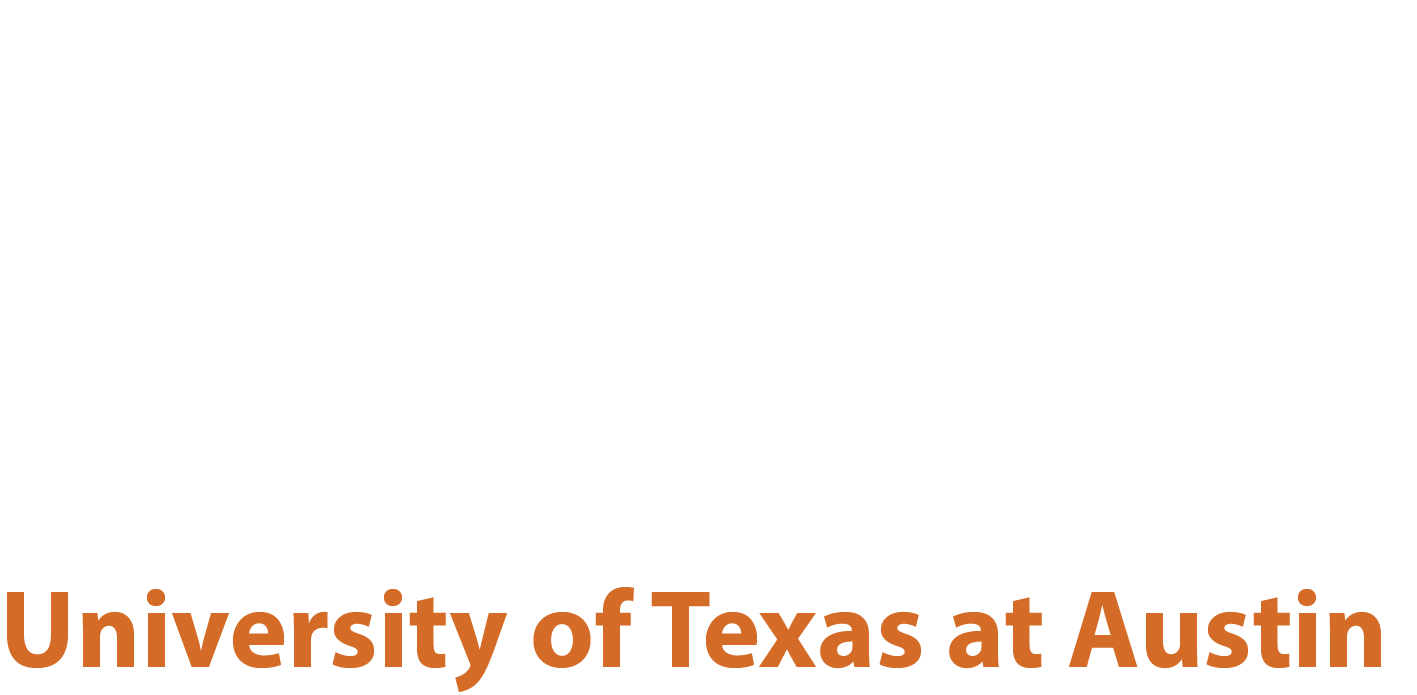

1) Coal is the mostly used fuel in power plants with conventional steam turbines (Figure 1). The process in coal-based plants may involve four cycles: fuel and ash cycle, air and gas cycle, feed water and steam cycle, and cooling water cycle. In the first cycle, the coal is prepared for burning to obtain the optimum energy. The preparation may involve pulverization, blending, mixing or washing off coals. The bottom ash produced after burning the prepared coal is collected in a storage unit while the fly ash is kept in flues and stored in silos. TPPs burning peat or fuel oil may also produce fly ash. The bottom and fly ash amounts differ depending on the type of the fuel. In natural gas power plants, these wastes are not expected to be formed.

Figure 1: Scheme of a typical coal-burning thermal power plant system with conventional steam turbines

Figure 1: Scheme of a typical coal-burning thermal power plant system with conventional steam turbines

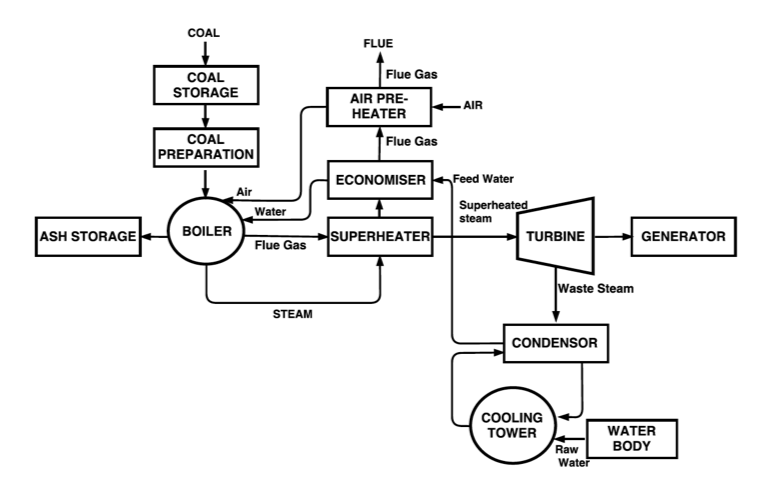

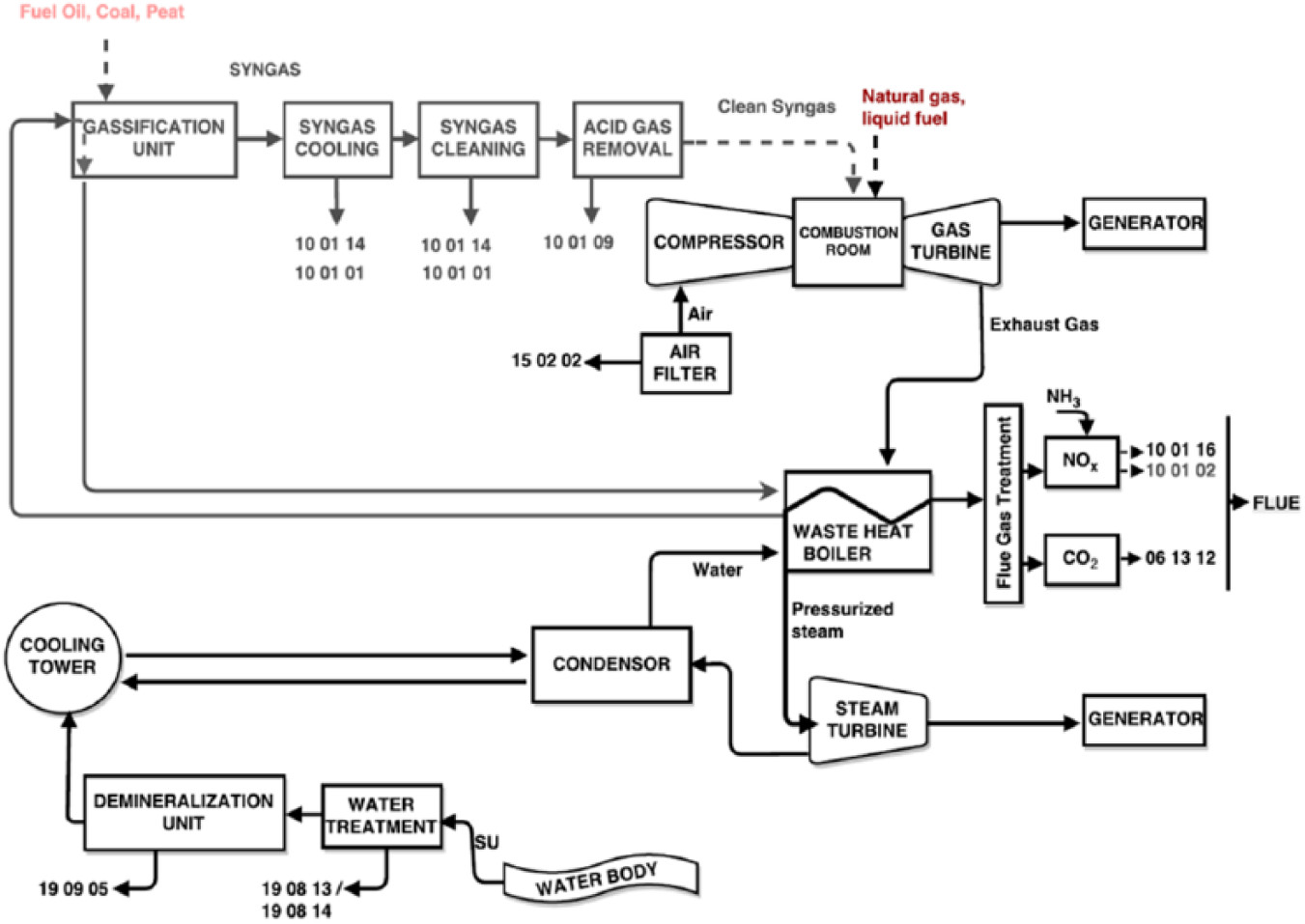

2) In electricity production, when the steam turbines used alone, the efficiency is less compared to combined cycle plants. In these systems, the steam turbines are held in operation together with gas turbines. Consequently, in combined cycle plants, with the same amount of fuel, electrical energy production can be made both from the steam and the gas turbines (Figure 2, left). The principal mechanism for electricity production is using the high temperature exhaust gases leaving the gas turbine in the water-steam cycle. In combined cycle plants, natural gas, crude oil, diesel fuel, fuel oil and coal can be used as fuel. However, the use of solid fuels in combined cycle plants requires a modification in the system. These modified systems are called Integrated Gasification Combined Cycle. It is preferred when low-calorie coal, high sulphur containing fuel-oil and petroleum coke are required as fuel in combined cycle plants. The modification comes from an additional gasification unit which burns the fuel and produces synthesis gas entering in the combined cycle system, eventually (Figure 2, right)

Figure 2: Combined Cycle Power Plants. (Left) Double handed electricity production scheme. (Right) Integrated gasification combined cycle plant scheme

Figure 2: Combined Cycle Power Plants. (Left) Double handed electricity production scheme. (Right) Integrated gasification combined cycle plant scheme

It’s highly important to manage thermal power plant wastes. It is power plant owners’ responsibility to appropriately take care of their wastes. Industries should be audited periodically to achieve a good waste management status.

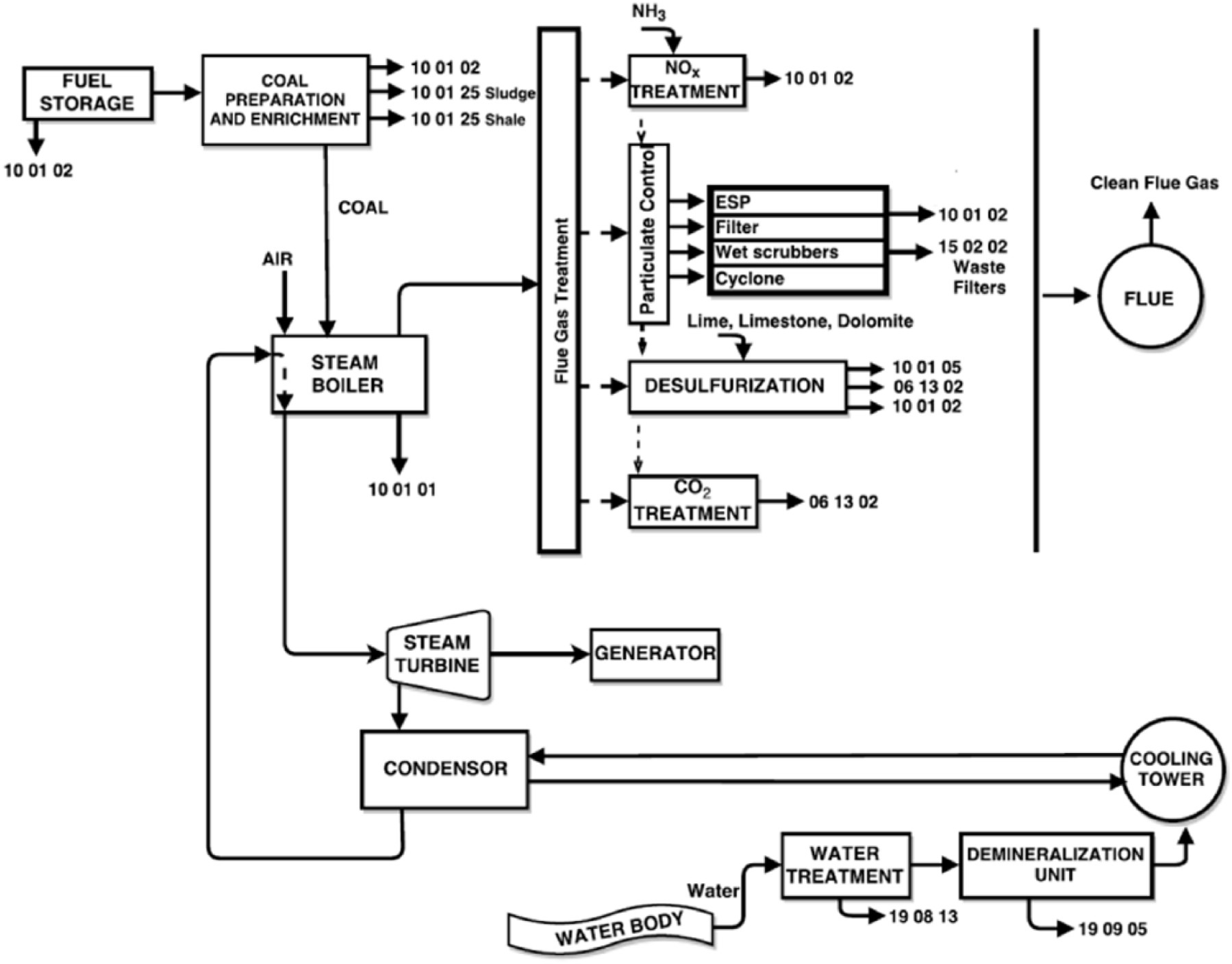

This project aims to help both the executive authorities and the industrialists by informing them about the types of wastes produced during the different thermal energy production processes, their European Waste Codes (NACE code D35.1.1) and how to manage them (Figure 3 & 4). In addition, our goal is to aid the authorities in monitoring the potential amounts of wastes produced, by providing them with the estimated waste generation factors (kg of waste/MWh of energy produced).

Figure 3: Coal-fired conventional steam turbine power plant scheme and waste points (Demir, et al., 2019)

Figure 3: Coal-fired conventional steam turbine power plant scheme and waste points (Demir, et al., 2019)

Figure 4: IGCC/combined cycle power plant scheme and waste points (Demir, et al., 2019).

Figure 4: IGCC/combined cycle power plant scheme and waste points (Demir, et al., 2019).

Information gathered from the site visits, responsible personnel and the literature was used to identify the possible wastes produced during the power production. The actual descriptions of the given waste codes can be accessed from European Waste Catalogue and Hazardous Waste List and/or Regulation on Waste Management published by Turkish Republic Ministry of Environment and Urbanization.

For more detail about this project and the estimated waste generation factors, please refer to our publication:

Demir C, Yetiş Ü, Ünlü K. Identification of waste management strategies and waste generation factors for thermal power plant sector wastes in Turkey. Waste Management & Research. 2019;37(3):210-218. doi:10.1177/0734242X18806995

This study was conducted in collaboration with the Turkish Republic Ministry of Environment and Urbanization, with the aim of preparing industry specific guidebooks (can be previewed below) to be distributed to the industries in Turkey.